Even though, in essence, apparel production is not a very complicated process, there are stages we need to see through carefully before garments can be sent out for production successfully. Each and every one of these steps comes with a fair share of sample making, testing, and adjusting.

There are several ways to go about garment sampling and it’s important to know and understand the different kinds that exist to see which ones work best for your production needs.

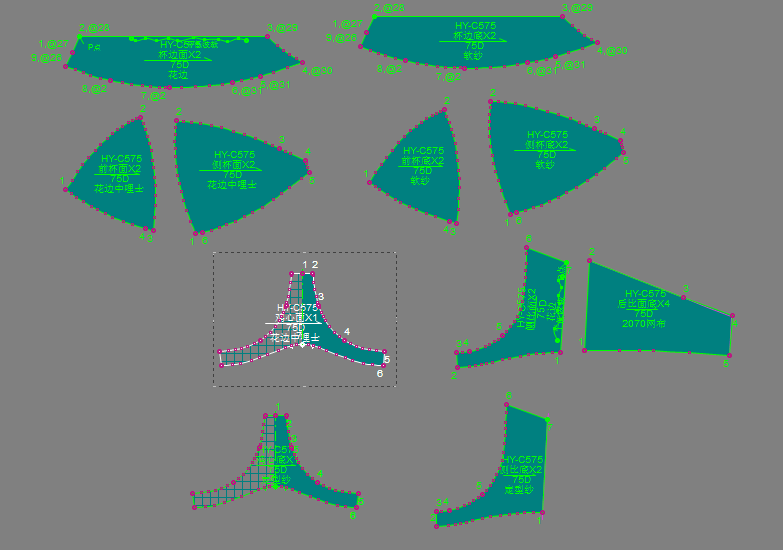

1, First sample / Trial Sample

Just make first sample based on design picture or design ideal. To make everythings get together as a garment sample.

2, Revised sample

Revised sample based on fitting comments on first sample. Adjust paper cutting ,and finalized the size chart as customer’s wanted.

3,Pre-production sample /Seal sample

After the approval of the PP sample, which signals the start of production, the Quality Control inspector representing a brand can visit the factory at any time and pick a garment from the production line for inspection. These samples are called “Top of production or TOP samples” and they are evaluated to ensure that the bulk production is of the same quality as the PP sample. TOP samples are also checked for their packaging.

4, Shipping sample

Once the bulk production is done and the shipment is finished, packed, and ready to go, a few samples are kept aside by the factory as shipment samples. These serve as to test the final product that will reach the brand; right from the folding to the packaging. Many brands will only approve shipping if the samples pass this test.